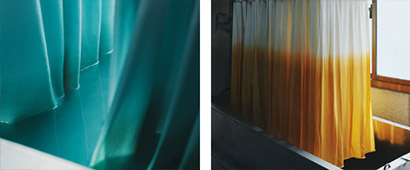

Raw yarn

We provide a wide range of different yarn types for diverse requirements and applications.

Our product line includes environmentally-friendly recycled yarn and upcycled yarn, as well as well as high-functionality modified cross-section fiber, etc.